WHO WE ARE

SET, Smart Equipment Technology, is a world leading supplier of high accuracy Flip-Chip Bonders and versatile Nanoimprint Lithography (NIL) solutions.

Since 1975, we have been designing and manufacturing semiconductor equipment dedicated to high precision applications.

We accompany laboratories and industries of semiconductor, which look for a high precision and an important reliability in the assembly of their components.

With Flip-Chip Bonders installed worldwide, SET is globally renowned for the unsurpassed sub-micron accuracy and the flexibility of its equipment.

Ranging from manual loading to fully automated version, our Flip-Chip Bonders cover a wide range of bonding applications and offer the unique ability to handle and bond fragile and small components onto substrate up to 300 mm.

Our Mission

Enable our customers to develop the chips and processes of the future.

Our Values

Customer Oriented

Our priority is providing the best support to our customers: from process definition to application support and machine configuration that fits best to the evolution of their needs.

Innovative

We are constantly developing new solutions and improving our equipment to better serve our customers’ technologies changing requirements.

Flexibility

If our numerous options and configurations do not correspond perfectly to your needs, we are pleased to design some special features to help you in your projects.

Partnership

SET team prefers long term collaboration and cooperation with employees, suppliers, partners and, of course, customers. As examples, Joint Development Projects or other types of partnership have been used for developing Triad 05 AP, NPS300 and Flip-Chip Bonders for direct bonding.

Awareness

SET team is very concerned by environmental preservation and will take all decisions in order to minimize impact on Nature.

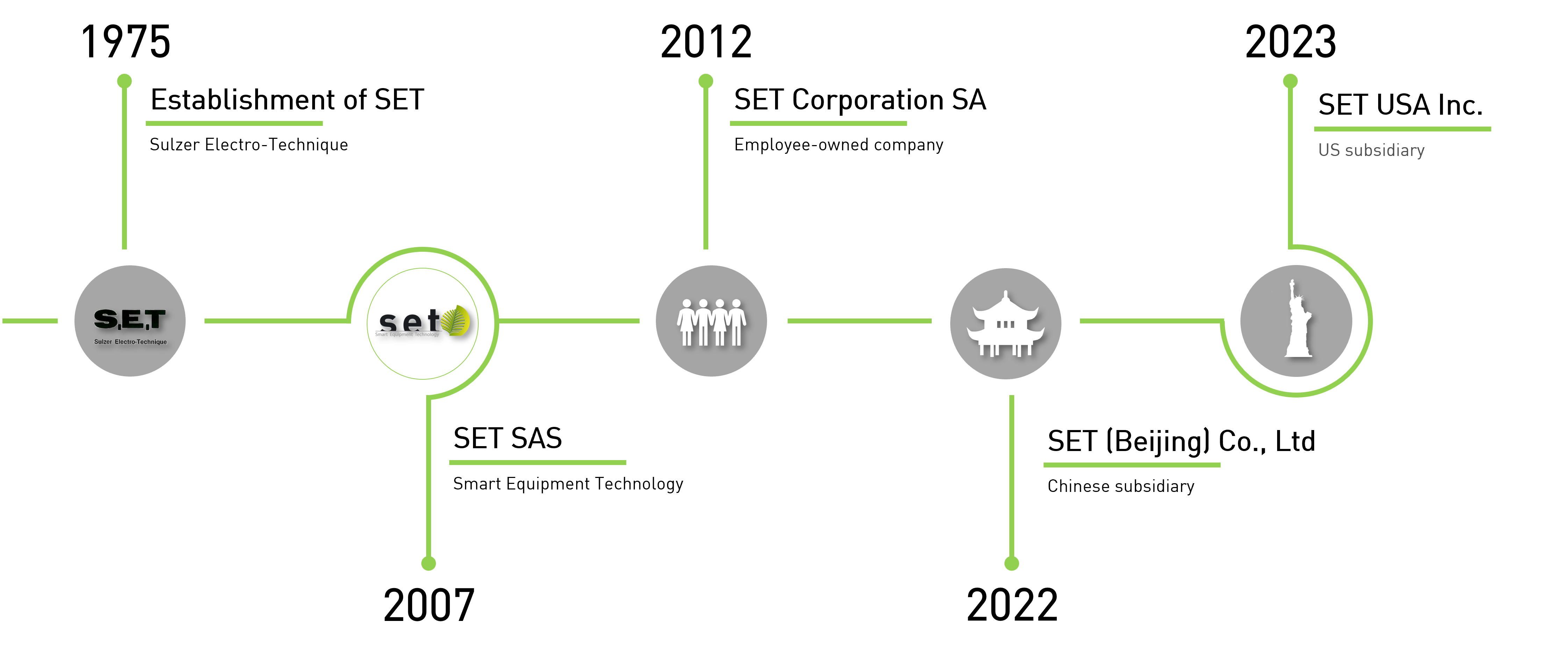

Our History

A Few Technical Milestones

- 1976 Optical sorting machine

- 1977 Semi-automated analytical probe station

- 1978 Mask aligner using X-Ray source

- 1978 Large photo-resist spin coater (flat panel displays)

- 1981 First commercially available Flip-Chip Bonder

- 1983 Wafer laser marker (patented robotic system)

- 1985 Automated probe station

- 1988 GYRSET system – Innovative spin coating concept: a huge step to unrivalled thickness uniformity and cost saving

- 1991 Innovative dispensing pump Virgin & Vulcan

- 1993 Large area mask aligner (12 & 16 inches)

- 1997 Market launch of the FC250 high accuracy production Flip-Chip Bonder

- 2004 Market launch of the Triad 0,5 AP high accuracy low force Flip-Chip Bonder

- 2005 Nano Imprinting Stepper NPS300; cooperation with VTT Microelectronics in the frame of the NaPa European Project

- 2007 Introduction of three innovative bonders: Kadett, FC300 and LDP150

- 2008 Transfer tool for ECPR

- 2010 First FC300 for HDD/HAMR applications. First FC300 dedicated to direct bonding, cooperation with CEA-Leti.

- 2011 Market launch of the FC300R pilot production for 3D

- 2014 Introduction of the ACCµRA100

- 2016 Introduction of the ACCµRA OPTO and of the ACCµRA M

- 2018 Introduction of the ACCµRA Plus

- 2019 Introduction of the NEO HB

- 2022 Introduction of the FC150 PLATINUM

- 2023 Introduction of the NEO W

de

de zh

zh en

en fr

fr