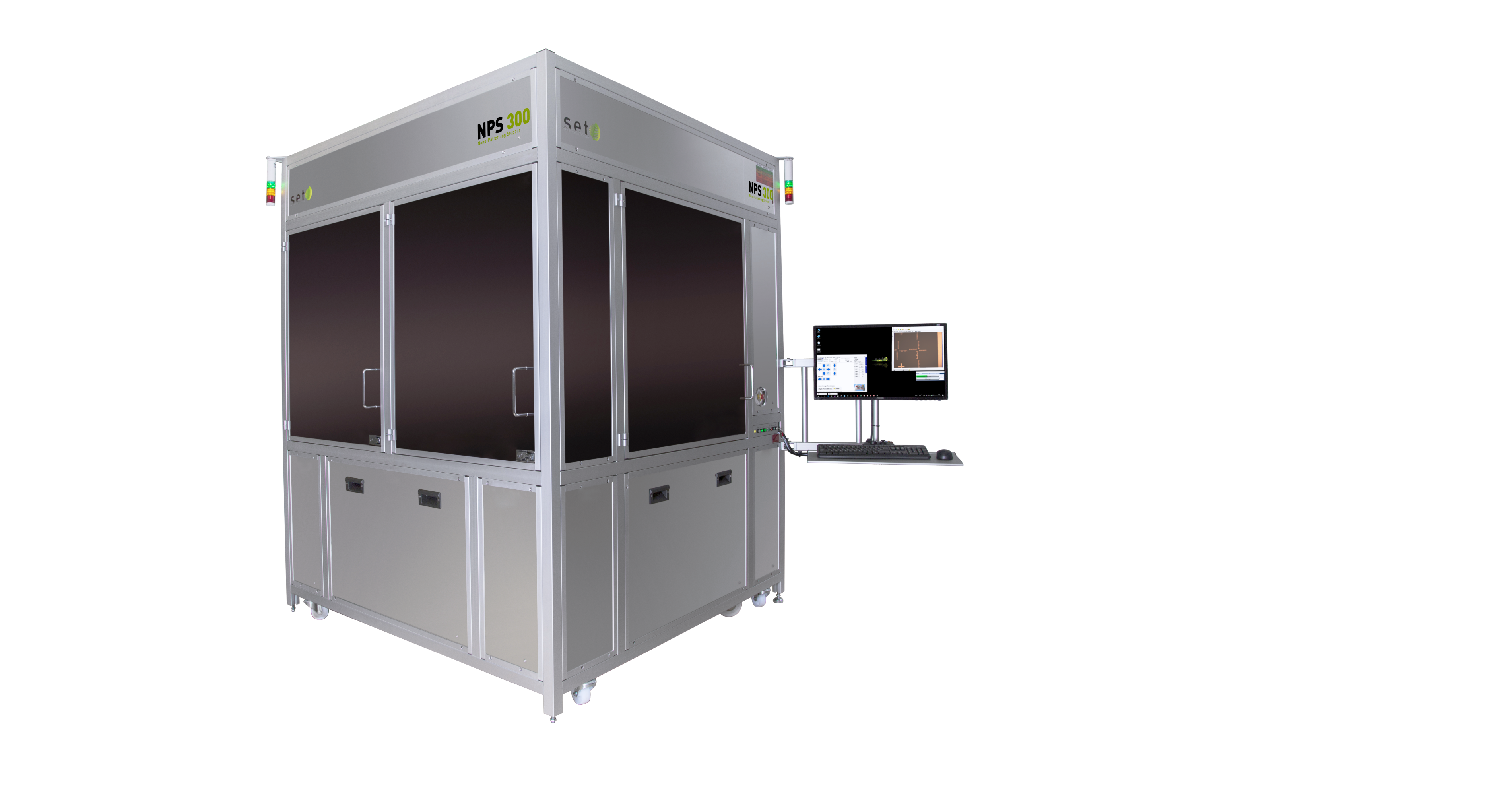

NPS300

Advanced R&D and pilot line-oriented, the NPS300 is a high accuracy, high force Stepper designed for nano-imprinting.

Optimized for replication of nanostructures at ± 0.5 μm accuracy, the NPS300 is the first-ever tool to combine aligned Hot Embossing Lithography and UV-NIL on the same platform.

The NPS300 can print sub-20 nm geometries with an overlay accuracy of 250 nm.

Its flexible architecture offers excellent process reproducibility and a unique ability to pattern large areas in a sequential Step & Repeat mode on wafers up to 300 mm.

The NPS300 also enables low-cost manufacturing of large stamps with repeated patterns.

000

Key benefits

- ± 0.5 μm accuracy

- Step & Repeat mode on wafers up to 300 mm

- Automatic stamp pickup

- Air-bearing technology and granite structure ensure long-term stability and reliability

- Control of parallelism guarantees exceptional accuracy, even under high forces

- Hands-free / fully automated calibration

- Automatic cycle and operator-independent

- High yield thanks to its stiff design

- Process recording for development / log files to track production

Process capabilities

Step & Stamp Imprinting Lithography for Hot Embossing and UV-NIL is an innovative method that was demonstrated at the VTT Technical Research Centre of Finland.

- Hot Embossing Lithography: involves controlling heat and pressure to transfer the stamp pattern into a thermoplastic embossing material.

- UV-NIL: uses in-situ imprinting material dispensing and UV curing. This cutting-edge technology is a very promising solution for replacing standard UV-lithography systems whenever sub-20 nm resolution is required.

Applications

- Photonic devices

- High-precision micro-optical arrays and gratings

- High-resolution OLED displays

- Large stamp creation

- Other emerging techniques

NIL technology

Low-cost nanostructure production solutions are in development today, and may be the driving force behind tomorrow’s semiconductor, MOEMS, and optoelectronics technology. In particular, Nanoimprint lithography (NIL) and its variations are being developed as a cost-effective alternative to high-resolution e-beam lithography for printing sub-20 nm geometries.

Imprinting in a thermo-mechanical or UV curing process is based on the principle of mechanically pressing thin polymer film with a stamp containing the nanopattern. The patterned polymer can act as a final device, e.g., lenses for imaging sensors, microfluidic chips, or biomedical arrays. It can also be used as a high-resolution mask for subsequent process steps.

Imprinting is a straightforward lithography technology with three basic process steps:

- Align the stamp with the substrate, which is pre-coated with the imprinting material

- Press the stamp into the imprinting material to transfer the pattern written on the stamp’s surface

We identify three imprinting or embossing techniques: Hot Embossing Lithography (HEL) using thermal plastic material, UV-NIL using a liquid resist that is cured with UV light after molding, and Soft Lithography, which uses a stamping method to transfer onto a substrate ink previously applied to a soft stamp.

Technical data

Click here to request the NPS300 datasheet.

en

en fr

fr de

de zh

zh