WHO WE ARE

SET (Smart Equipment Technology) is a world-leading supplier of high-accuracy Flip-Chip Bonders and versatile Nanoimprint Lithography (NIL) solutions. Since 1975, we have designed and manufactured leading-edge semiconductor equipment for high-precision applications.

We support laboratories and semiconductor companies seeking world-class precision and superlative reliability in the assembly of their components. With our Flip-Chip Bonders installed worldwide, SET’s equipment is globally renowned for unsurpassed sub-micron accuracy and incomparable flexibility.

Ranging from manual-loading to fully-automated solutions, our Flip-Chip Bonders cover a wide range of bonding applications and possess the unique ability to handle and bond fragile and/or small components onto substrates up to 300 mm.

Our Mission

Help our customers to develop the chips and processes of the future.

Our Values

Customer Oriented

Priority #1 for SET is providing the best support for our customers, from process definition and application expertise to the machine configuration that best fits their evolving needs.

Innovative

We are constantly developing new solutions and refining our equipment to better serve our customers’ varied technological requirements.

Flexibility

If none of our numerous options and configurations correspond perfectly to your needs, we can customize a solution that meets your exact objectives.

Partnership

SET strives for long-term collaboration and cooperation with its employees, suppliers, partners, and of course, its customers. Examples of joint development projects and other types of alliances include the development of Triad 05 AP, NPS300, and Flip-Chip Bonders for direct bonding.

Awareness

SET is committed to preserving the environment. All company decisions are made with an eye towards respecting Nature.

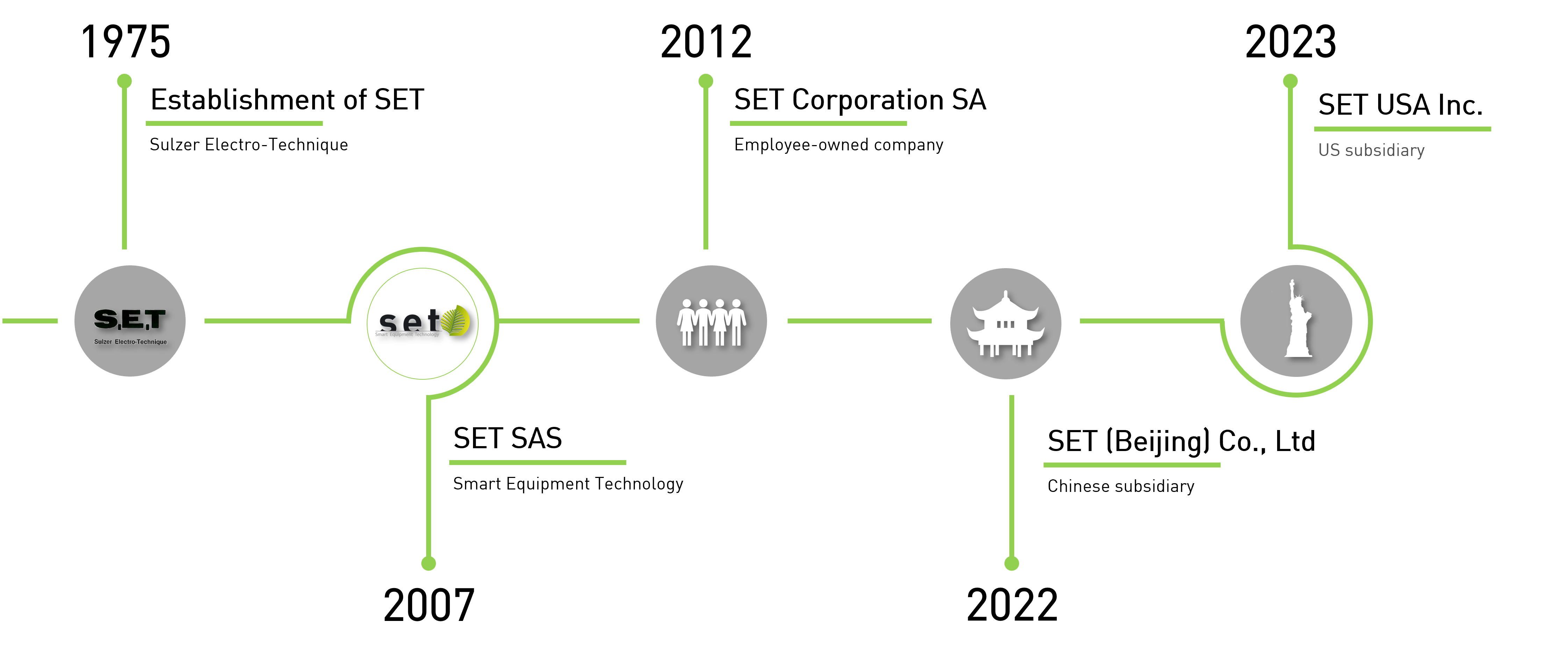

Our History

A Few Technical Milestones

- 1976: Optical sorting machine

- 1977: Semi-automated analytical probe station

- 1978: Mask aligner using X-Ray source

- 1978: Large photoresist spin coater (flat-panel displays)

- 1981: First commercially available Flip-Chip Bonder

- 1983: Wafer laser marker (patented robotic system)

- 1985: Automated probe station

- 1988: GYRSET system – an innovative spin-coating concept and a huge step towards unrivalled thickness uniformity and cost-savings

- 1991: Innovative Virgin & Vulcan dispensing pump

- 1993: Large-area mask aligner (12 & 16 inches)

- 1997: Market launch of the FC250 high-accuracy-production Flip-Chip Bonder

- 2004: Market launch of the Triad 0.5 AP high-accuracy, low-force Flip-Chip Bonder

- 2005: Nanoimprinting stepper, NPS300 – collaboration with VTT Microelectronics as part of the NaPa European Project

- 2007: Introduction of three innovative bonders – Kadett, FC300, and LDP150

- 2008: Transfer tool for ECPR

- 2010: First FC300 for HDD/HAMR applications and the first FC300 dedicated to direct bonding (in cooperation with CEA-Leti)

- 2011: Market launch of the FC300R pilot production for 3D

- 2014: Introduction of the ACCµRA100

- 2016: Introduction of the ACCµRA OPTO and ACCµRA M

- 2018: Introduction of the ACCµRA Plus

- 2019: Introduction of the NEO HB

- 2022: Introduction of the FC150 PLATINUM

- 2023: Introduction of the NEO W

de

de zh

zh en

en fr

fr