Direct Bonding

Process

Used to assemble two components, Direct / Hybrid Bonding offers three important advantages:

- Low bonding force

- Bonding process at room temperature

- Short process cycle

However, there is one challenge at the bonding step: the components must possess a very high level of cleanliness.

Technology benefits

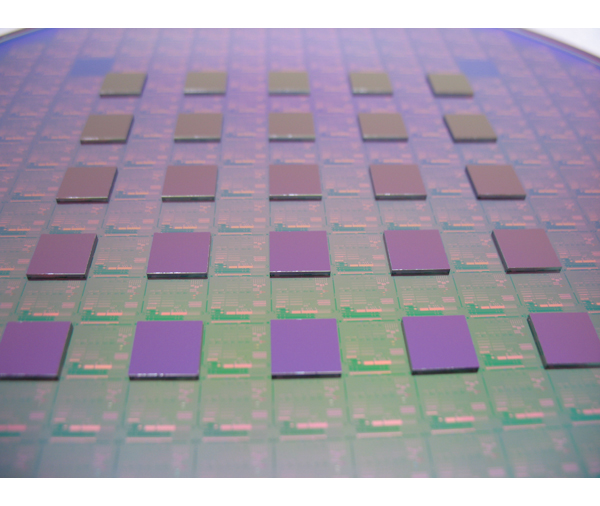

The bonding process requires low force and room temperature to circumvent the thermal expansion of different materials This enables high-accuracy bonding for high-density interconnections.

To ensure void-free bonding, the alignment and bonding steps must occur in a particle-free environment. This is accomplished through the use of special materials and careful airflow management.

All of these advantages allow for reaching the high throughput required for widespread adoption of 3D Integration.

Comprehensive experience

During the PROCEED Project, SET used a specially-designed FC300 to successfully demonstrate the feasibility of a Die-to-Wafer approach using Direct / Hybrid Bonding with an accuracy < 1μm. Our efforts were the subject of numerous articles.

At the end of 2015, SET joined IRT Nanoelec in designing a rapid, high-accuracy Flip-Chip Bonder dedicated to Direct / Hybrid Bonding. Capitalizing on the experience gained from the PROCEED Project, SET designed and developed the NEO HB for production.

In 2019, SET launched the NEO HB at SEMICON Taiwan, thus meeting the high throughput necessary for widespread adoption of 3D Integration.

de

de zh

zh en

en fr

fr