SET SUCCESS STORY at RWTH Aachen University, Germany

Interview with Dr.-Ing. Alexander Stippich – Chief Engineer at the Institute for Power Electronics and Electrical Drives

Tell us about RWTH Aachen University. What are you specialized in?

RWTH Aachen University is one of Germany’s largest technical universities and covers a wide range of teaching and research areas, e.g., Mathematics, Computer Science, Architecture, Mechanical and Electrical Engineering.

The Institute for Power Electronics and Electrical Drives is part of the Faculty of Electrical Engineering and Information Technology. Our research is in the field of modeling and advanced control of electrical machines, the modeling, design and control of efficient power electronic converters as well as the modelling and analysis of battery and energy storage systems from cell to the system level.

In the new research center CARL (Center for Ageing, Reliability and Lifetime Prediction of Electrochemical and Power Electronic Systems), the power electronics group will focus on concepts of intelligent monitoring algorithms to detect ageing defects in power electronic modules.

Additionally, the design of highly integrated and reliable power electronic modules for wide bandgap devices for power converters with high power densities is of interest.

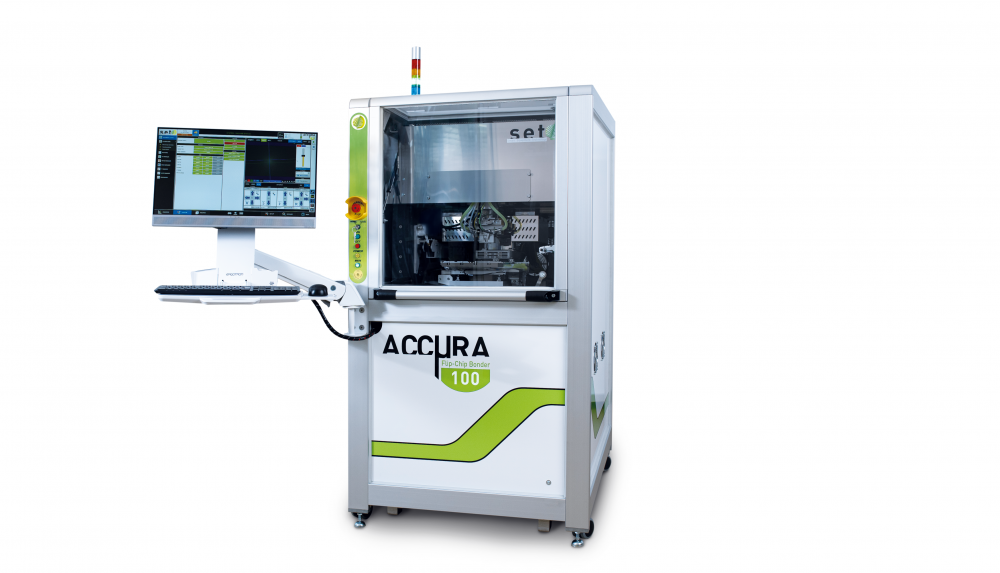

Why did you buy an ACCµRA100?

Our goal is to research and design novel power module designs with superior electrothermal properties and reliability. The ACCµRA100 helps us achieving this goal through its high placement accuracy combined with the high bond force and temperature that enables silver sintering of power semiconductors on substrates. It is an essential part of our prototype production of power electronic modules.

What kind of applications are you developing with it?

We want to build our own custom highly integrated power semiconductor modules with advanced packaging technologies such as silver sintering. The ACCµRA100 will be used to explore new designs of power modules with better electrical and thermal capabilities. It will be used to manufacture low-inductive modules for fastest switching transients of semiconductors combined with excellent cooling capabilities.

de

de zh

zh en

en fr

fr